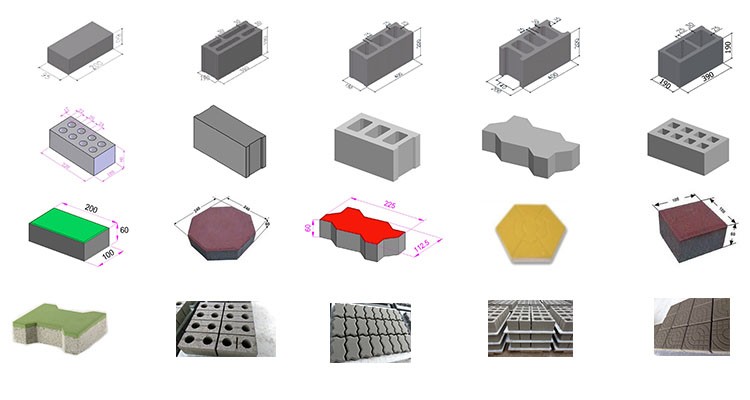

Nanning SHENTA Machinery Equipment Co., Ltd, established in 1973, is the earliest professional and leading manufacturer of concrete block making machinery. SHENTA factory covers an area of 40,000 square meter, with senior engineers more than 20 people and all kinds of technician more than 200 staff.SHENTA not only distributed in all around China, but also exported to Southeast Asia, Africa, and Oceania etc.