86-771-3815999

No. 139, Gaoshan 2nd Road, Wuxu Town, Nanning, Guangxi, China (Mainland)

QTJ4-25 semi-auto cement brick and block machine

I. Our Advantages of semi-auto cement brick and block machine

1)We are brick and block making machine manufacturer with 40 years professional experience.

2) We can offer machines to meet large scale, millde and small scale business.

3) We have more than 40,000 square meters production area with over 200 workers.

4)Welcome to visit Shenta factory.

II.QTJ4-25 semi-auto cement brick and block machine

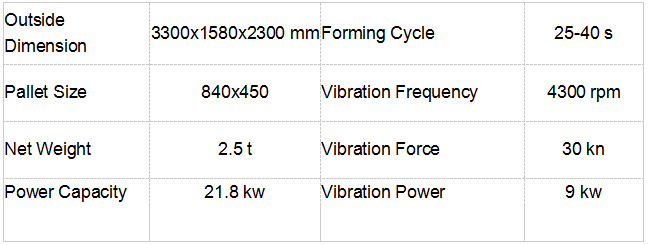

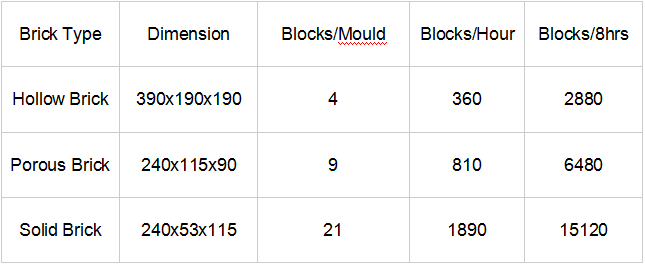

Main specification

Theoretic Productivity

III.Characteristic of semi-auto cement brick and block machine

1.QTJ4-25 concrete block forming machine is to meet the market demand of small and midium size brick factory and removeble brick factory.

2.Adopt multisource vibration technology. Bricks formed by synchronous vibrations of press head and mould table, which makes the forming speed faster and the bricks denser.

3.By changing different mold, the QTJ4-25 concrete block forming machine can produce different hollow brick, porous brick and cement solid brick.

4.QTJ4-25 concrete block forming machine has the advantage of compact structure, reliable operation, low malfunction rate, and easy maintenance and transportation.

5.It is made of high strength steels according to the national standard.Special welding techniques and advanced mechanical working processed bring high precision,durable and a lone service life.

IV.Brick sample of QTJ4-25 semi-auto cement brick and block machine

By changing different mold, the QTJ4-25 semi-automatic block machine can produce different hollow brick, porous brick and cement solid brick. Special brick model is available according with customer demand.

V.Raw materials for QTJ4-25semi-auto cement brick and block machine

Our brick machines can meet all various of concrete materials, the rough crushed stone, cobblestone, sand, fly ash, even the construction refuse, waste clay brick (after crushed) are available.

Recommended Material Rate:

(for MU10 Grade Brick Strength)

1) Cement : 10%

2) Fly Ash : 10%

3) Fine Sand (or Stone Powder): 30%

4) Crushed Stone (<10mm): 50%

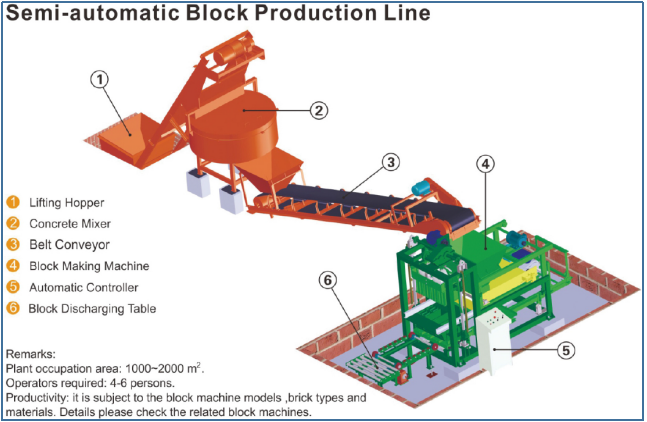

VI.Production line of QTJ4-25 semi-auto cement brick and block machine

Our company can provide the compact production line machines to meet customers' need.

VII. The reason for choosing our QTJ4-25semi-auto cement brick and block machine

1. Large material hopper, storage more concrete materials.

2. Material feeding motor and feeding arm is strong, easy to feed the crude concrete materials.

3. Material feeding height is adjustable, so the machine can form different block height, you can form block height from 60mm~200mm .

4. Pallet hopper, the user can put 10~15 pieces pallets here one time. The machine can feed pallet automatically one by one, save the operator feeding time, shorten the forming cycle period, increase the working efficiency, reduce the labor intensity,

5. Our machine’s frame use thick square steel tube, machine is strong, service life more than 10 years.

VII.Packaging & Shipping

Experienced and benefited from over 30 countries in the past years.We can make a almost perfect packaging and shipping method for customers.All the key parts are protected by wooden boxes.Please contact with us for further information.

Fig.9

VIII.About us

1.SHENTA Machinery Equipment Co.,Ltd, established in 1973, is the earliest professional manufacturer of concrete block making machine. Moreover,SHENTA is also one of the largest manufacturer of block making equipment.It covers an area of 40000 m*m,which locate in Nan Ning of Guang Xi,China.

Fig.10

2. Certification of our automatic hydraulic block machine

Fig.11

3.Exhibitions

We take parts in many exhibitions every year, such as Canton Fair in Guangzhou; India international engineering machinery, building materials machinery, mining machinery, engineering vehicles and parts exhibition; International concrete technology and equipment exhibition in India; The ASEAN-China Exposition in Nanning, etc.

VIIII.Make win-win mode

Pre-sale:

-Analyze the customer’s need and factory layout design, confirm scale of operation;

-Recommend the fitting choice;

-Provide best solution to set up a factory.

Sales:

-Help to set up the factory;

-Provide free service of installation and commissioning;

-Provide training for operators and maintenance person.

After-sale:

-Help customers to establish production craft formula;

-Provide the consultation all the time;

-Supply moulds and parts all the time.

Buying tips:

We'd like to offer you the block making machine. (we involve small scale, middle scale, and large scale machine);

when you want to buy,

Please tell me:

1.Your blocks’ size ( length, width and height);

2.Your blocks’ picture (If you have);

3.Your production blocks /days

Q1: What is the standard packing for the brick machine?

A1: It depends. If necessary, wooden cases with fumigation are available.

Q2: If OEM and ODM services available?

A2: Yes. We can make the machines with customers’ brand and logo. With professional engineers, we can also design and produce the machines according to customers’ requests.

Q3: What is the production lead time?

A3: Normally, if the brick machine are standard, it will be 35 to 40 days. If not, the production lead time will be longer.